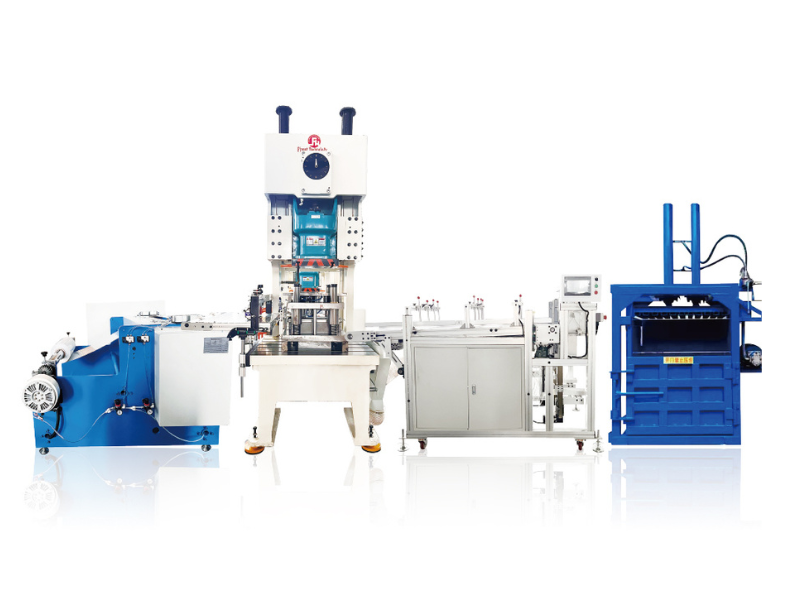

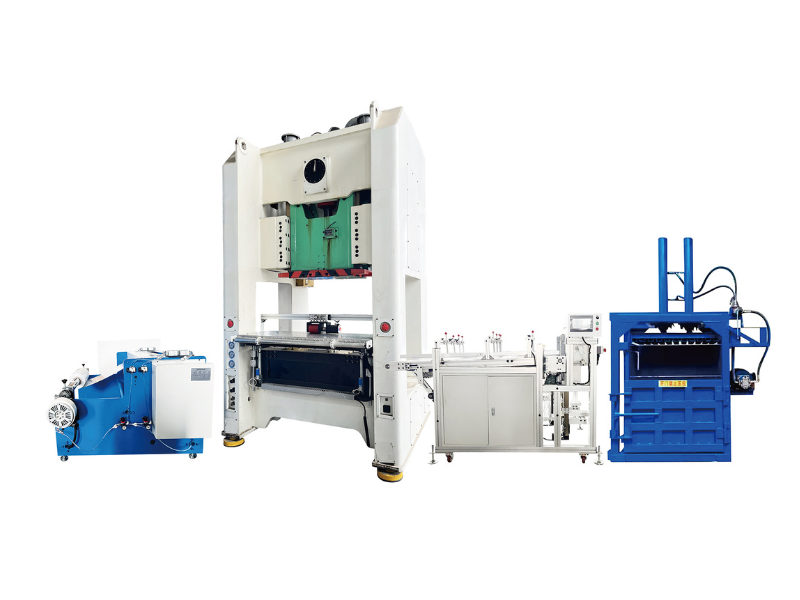

Full Aluminum Foil Production Line

It adopts an advanced high-speed pneumatic punching machine as the main body, and refers to the advanced feeder structure of Italy to increase production and save labor costs.

- The punching machine is designed to 50 years.

- Utilize Siemens PLC brand inverters to guarantee system safety and reliability.

- Provide multiple tonnage options such as 45T/63T/80T/130T/200T