Introduction to Slitting Machines

- Slitting machines, also known as slitter rewinders, are essential equipment in the converting industry for cutting large rolls of material into narrower rolls.

- The slitting process involves cutting a master roll into desired widths using various slitting methods, including shear slitting, razor slitting, and crush slitting.

- Slitting machinery is designed to handle different types of materials, such as paper, plastic films, and foil, with high precision and efficiency.

- Understanding how a slitting machine works is crucial for optimizing production and minimizing waste in the converting industry.

- Slitting machines are widely used in various industries, including packaging, manufacturing, and labeling.

Types of Cutting Methods

- Shear slitting is a common method used for cutting thin materials, such as paper and plastic films, with high precision and accuracy.

- Razor slitting is another popular method used for cutting narrower strips of material, such as labels and tapes.

- Crush slitting, also known as score slitting, is used for cutting thicker materials, such as cardboard and foam.

- The choice of slitting method depends on the type of material, desired width, and quality of the cut.

- Different types of slitting machines are designed to handle specific cutting methods and materials.

Slitter Rewinder Machines

- Slitter rewinder machines are designed to unwind a master roll, cut it into desired widths, and rewind the slit material onto new cores.

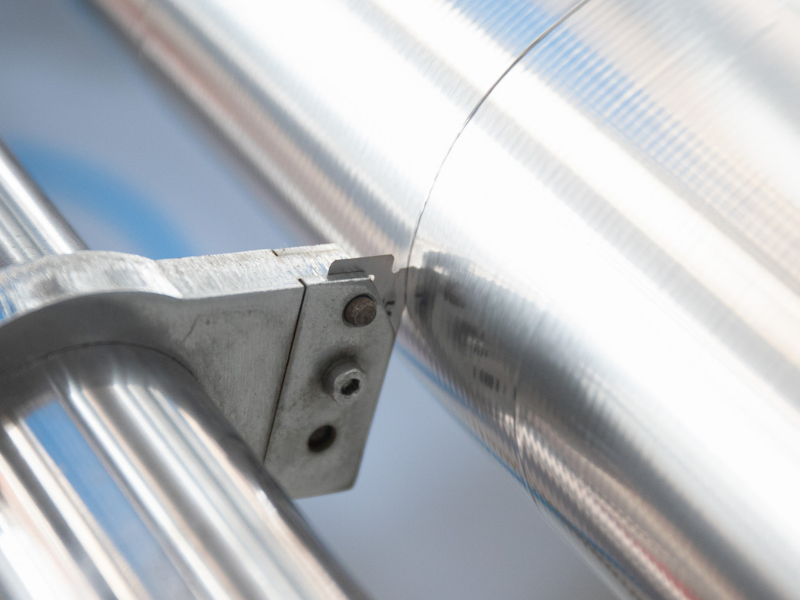

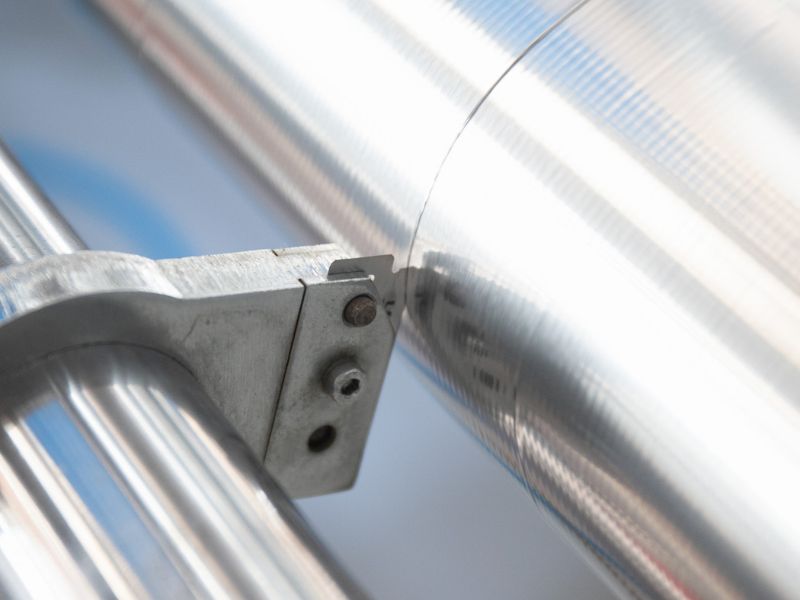

- These machines are equipped with various features, such as tension control systems, blade positioning, and rewind diameter options.

- Slitter rewinders are commonly used in the converting industry for producing standard sized rolls and custom widths.

- The slitting machine work process involves three main components: unwind, slitting, and rewind.

- Slitter rewinder machines are available in different types, including wide-web and narrow-web machines.

Log Slitting Process

- Log slitting is a process that involves cutting a large roll of material into smaller rolls without fully unwinding it.

- This method is commonly used for producing small rolls of material, such as adhesive tapes and labels.

- Log slitting machines are designed to handle large rolls of material and cut them into desired widths with high precision.

- The log slitting process is faster and more efficient than traditional slitting methods.

- Log slitting machines are ideal for high-volume production and minimize waste.

Selecting the Right Slitting Machine

- Selecting the right slitting machine depends on various factors, including the type of material, desired width, and production volume.

- The right slitting machine should be able to handle the specific material and cutting method required.

- Slitting machines are available in different types, including roll slitters and slitter rewinders.

- The choice of machine depends on the specific application and production requirements.

- It is essential to consider factors such as machine speed, accuracy, and maintenance when selecting a slitting machine.

Roll Slitters and Their Applications

- Roll slitters are designed to cut large rolls of material into smaller rolls without rewinding.

- These machines are commonly used in various industries, including packaging, manufacturing, and labeling.

- Roll slitters are ideal for cutting thin materials, such as paper and plastic films.

- The roll slitting process involves cutting the material into desired widths using a blade or razor.

- Roll slitters are available in different types, including manual and automatic machines.

Slitter Machines and Their Uses

- Slitter machines are widely used in the converting industry for cutting large rolls of material into narrower rolls.

- These machines are designed to handle different types of materials, including paper, plastic films, and foil.

- Slitter machines are used in various applications, including packaging, manufacturing, and labeling.

- The slitting machine work process involves three main components: unwind, slitting, and rewind.

- Slitter machines are available in different types, including wide-web and narrow-web machines.

Different Types of Slitting Solutions

- There are various types of slitting solutions available, including shear slitting, razor slitting, and crush slitting.

- Each type of slitting solution is designed to handle specific materials and cutting methods.

- The choice of slitting solution depends on the type of material, desired width, and quality of the cut.

- Slitting solutions are available in different types, including roll slitters and slitter rewinders.

- The right slitting solution should be able to handle the specific material and cutting method required.

Slitting Machine Efficiency and Productivity

- Slitting machine efficiency and productivity depend on various factors, including machine speed, accuracy, and maintenance.

- Regular maintenance is essential to ensure optimal performance and minimize downtime.

- Slitting machines are designed to handle high-volume production and minimize waste.

- The slitting machine work process involves three main components: unwind, slitting, and rewind.

- Slitting machines are available in different types, including wide-web and narrow-web machines.

Maintenance and Troubleshooting Techniques

- Regular maintenance is essential to ensure optimal performance and minimize downtime.

- Troubleshooting techniques involve identifying and resolving issues with the machine.

- Common issues with slitting machines include blade wear, tension control, and rewind diameter problems.

- Maintenance and troubleshooting techniques are essential to ensure efficient and productive operation.

- It is essential to follow the manufacturer’s instructions for maintenance and troubleshooting.

Customization and Automation Options

- Slitting machines are available with various customization and automation options.

- These options include tension control systems, blade positioning, and rewind diameter options.

- Automation options, such as programmable logic controllers, can improve efficiency and productivity.

- Customization options, such as custom widths and materials, can enhance the versatility of the machine.

- Slitting machines can be integrated with other equipment, such as die cutters and printers.